TAAAC Thermal-Resistant All Aluminum Alloy Conductor

TAAAC Thermal-Resistant All Aluminum Alloy Conductor

TAAAC or TAL Conductor

High Temperature Conductor

Application

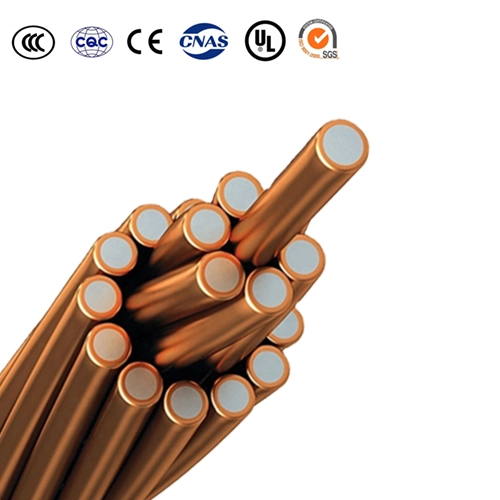

TAAAC is a concentrically stranded conductor composed of thermal resistant aluminum alloy wires (TAL).

TAAAC conductor is used in the transformation of old lines, urban network capacity transformation, substation, power plant construction and general lines.

Specifications

● IEC 61089 Round Wire Concentric Lay Overhead Electrical Stranded Conductors

● IEC 62004 Thermal -Resistant Aluminum Alloy Wires For Overhead Line Conductor

Parameter

| Nominal Area | Calculated Cross Sect. Area |

No. of Wires | Diameter of Wires | Approx. Overall Diameter |

Approx. Weight |

Calculated Breaking Load |

Max. D.C. Resistance at 20°C |

| mm² | mm² | No. | mm | mm | kg/km | kN | Ω/km |

| 150 | 152.8 | 19 | 3.2 | 16.0 | 419 | 22.3 | 0.191 |

| 200 | 204.3 | 19 | 3.7 | 18.5 | 560 | 29.8 | 0.143 |

| 240 | 238.8 | 19 | 4.0 | 20.0 | 654 | 34.2 | 0.122 |

| 300 | 297.6 | 37 | 3.2 | 22.4 | 820 | 43.4 | 0.0985 |

| 400 | 397.8 | 37 | 3.7 | 25.9 | 1097 | 58.0 | 0.0737 |

| 510 | 512.6 | 37 | 4.2 | 29.4 | 1413 | 73.3 | 0.0571 |

| 660 | 655.9 | 61 | 3.7 | 33.3 | 1812 | 95.6 | 0.0448 |

| 850 | 845.1 | 61 | 4.2 | 37.8 | 2334 | 120.9 | 0.0347 |

| 980 | 978.4 | 91 | 3.7 | 40.7 | 2716 | 142.7 | 0.0302 |

| 1030 | 1032.0 | 91 | 3.8 | 41.8 | 2865 | 150.5 | 0.0286 |

| 1260 | 1260.8 | 91 | 4.2 | 46.2 | 3499 | 180.3 | 0.0234 |

| 1600 | 1595.9 | 127 | 4.0 | 52.0 | 4438 | 228.5 | 0.0186 |

| 2020 | 2019.8 | 127 | 4.5 | 58.5 | 5617 | 289.0 | 0.0147 |

| 2500 | 2493.6 | 127 | 5.0 | 65.0 | 6935 | 357.0 | 0.0118 |

| Cross

Sectional area |

Na/Dia of wire | Approximately | DC conduvtor

Resistance at 20℃,max |

Calcuated breaking load min | Current

Carrying capacity |

Standard

Delivery lenght |

||

| Overall

diameter |

Net weight | |||||||

| mm² | Pcs/mm | mm | Kg/km | Ω/km | kgf | n | A | m |

| 150 | 19/3.20 | 16 | 419 | 0.1910 | 2270 | 22268 | 700 | 5000 |

| 200 | 19/3.70 | 18.5 | 560 | 0.1430 | 3030 | 29724 | 850 | 5000 |

| 240 | 19/4.00 | 20 | 655 | 0.1220 | 3490 | 34236 | 945 | 3000 |

| 300 | 37/3.20 | 22.4 | 821 | 0.0958 | 4430 | 43458 | 1090 | 3000 |

| 400 | 37/3.70 | 25.9 | 1097 | 0.0737 | 5890 | 57780 | 1325 | 2000 |

| 510 | 37/4.20 | 29.4 | 1414 | 0.0571 | 7460 | 73182 | 1565 | 2000 |

| 660 | 61/3.70 | 33.3 | 1812 | 0.0448 | 9720 | 95353 | 1840 | 1500 |

| 850 | 61/4.20 | 37.8 | 2335 | 0.0347 | 12300 | 120663 | 2175 | 1000 |

| 980 | 91/3.70 | 40.7 | 2716 | 0.0302 | 14500 | 142245 | 2380 | 1000 |

| 1030 | 91/3.80 | 41.8 | 2865 | 0.0286 | 15320 | 150289 | 2465 | 1000 |

| 1260 | 91/4.20 | 46.2 | 3501 | 0.0234 | 18350 | 180013 | 2800 | 500 |

PDF Download

PDF Download

Why Choose Us

Contact Us Immediately

Contact Us

- 24-hour online service

- Own factory processing

Product Category

hot-sale product

MOQ: 5KM Factory from China

25mm 50mm 95mm 100mm ACSR Conductor

Overhead Line Cable

Aluminium Conductors with a steel support core for use in overhead transmission and distribution lines.

Dead Soft Annealed (DSA) Copper Clad steel (CCS) conductors are a concentric lay-stranded construction. The CCS strands are a 40% conductivity grade of material using a low carbon steel core rendering greater flexibility to enable easier handling during installation.

ACS Wire Manufacturers

Aluminium Clad Wire (ACS) Manufacturer

Bare Overhead Transmission Conductor

Distribution Conductor and Messenger Support

Steel Core Aluminum Alloy Stranded Wire